Technology of production of spherical titanium powders

Titanium powder is a versatile metallic material valued for its unique combination of high strength, low density, corrosion resistance and biocompatibility. Titanium powders are processed using advanced manufacturing technologies such as metal injection molding (MIM), additive manufacturing (AM), hot isostatic pressing (HIP), compaction and powder metallurgy (PM) sintering to create complex titanium components.

In recent years, JSC “Titanium Institute” has been actively developing and mastering highly efficient innovative technologies for the production of titanium powders, products made from them, as well as their use in various industries, including additive technologies.

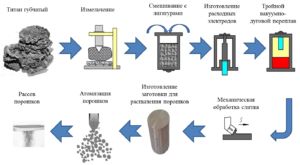

In light of modern trends in the development of additive processes, the most promising and cost-effective method for producing titanium and titanium alloy powders for 3D processes is the technology of hydrogenation-dehydrogenation of titanium materials followed by spheridization in plasma.

JSC “Titanium Institute” offers for implementation the developed innovative highly efficient technology of hydrogenation-dehydrogenation of alloyed titanium with a closed cycle of hydrogen use. As a result of such technological processes, it is possible to obtain non-spherical (and spherical when using a spheridizer) titanium and titanium alloy powders for the manufacture of parts using powder metallurgy and additive technologies, including for the needs of the aerospace industry.

APPLICATION

- Aerospace engineering

- Automotive industry

- Chemical industry

- Oil and Gas industry

- Medical

- Power Generation industry

- Sporting Goods

- Consumer Goods

PRODUCTION

Spheridization of titanium powders is performed by our partner, MULTIFLEKS LLC.

MULTIFLEKS LLC is a manufacturer of spherical metal powders from various alloys. It produces powders for additive technologies, fusing and spraying from titanium, nickel, iron, cobalt and other alloys.

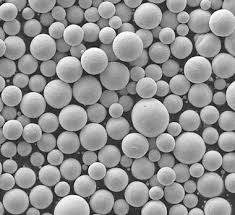

The spheridization technology used by MULTIFLEKS LLC guarantees the chemical and granulometric composition and shape of the powders.

Advantages of the technology

- the powders are of high quality and can be used in the aerospace industry, mechanical engineering, and medicine;

- the powders have an ideal spherical shape, they do not have satellites and internal pores, which is typical for powders obtained by gas atomization.

Get a free consultation and presentation of our technologies!

Fill out the form and our experts will contact you to discuss the details, answer your questions, and offer the best solutions for your business. In the “Message text” field, briefly write what you are interested in.