Technology of low-cost titanium powder production by hydrogenation-dehydrogenation method

Titanium powders are in high demand due to their unique properties, which makes them ideal for use in high-tech industries.

JSC “Titanium Institute” has been actively developing and mastering highly efficient innovative technologies for the production of titanium powders, products made from them, as well as their use in various industries, including additive technologies, in recent years. In light of modern trends in the development of additive processes, the most promising and cost-effective method for producing titanium powders and titanium alloys for 3D processes is the technology of hydrogenation-dehydrogenation of titanium materials followed by spheridization in plasma.

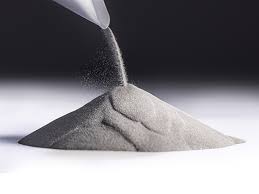

JSC “Titanium Institute” offers an innovative technology for the production of low-cost titanium powders by the hydrogenation-dehydrogenation method from titanium sponge or other titanium-containing materials of various quality and fractional composition.

As a result of such technological processes, it is possible to obtain non-spherical (and, when using a spheridizer, spherical) titanium and titanium alloy powders for the manufacture of parts using powder metallurgy and additive technologies, including for the needs of the aerospace industry.

APPLICATION

- Aerospace industry

- Automotive industry

- Metallurgy

- Chemical industry

- Oil and gas industry

- Medicine

- Power generation

- “Low cost” series products — rod semi-finished products, hardware group, shut-off valves, flanges, special geometry parts, finished products of complex shape;

- products similar in characteristics to serial cast and deformed alloys of the VT5, VT6, VT1-0 type, etc. — rod semi-finished products, hardware group, shut-off valves, flanges, special geometry parts, finished products of complex shape.

- Sporting Goods

- Consumer Goods

PRODUCTION

Based on the presented technology, JSC “Titanium Institute” can design the production of titanium powders of the required productivity.

The technological process provides the ability to vary the quality of powders and their fractional, chemical composition, content of oxygen, nitrogen, iron, nickel, magnesium, aluminum, vanadium, as well as the production of high-quality powders of the required granulometric composition (40-100 μm) for additive technologies, synthesis of products by powder metallurgy methods, surfacing, spraying, etc.

Get a free consultation and presentation of our technologies!

Fill out the form and our experts will contact you to discuss the details, answer your questions, and offer the best solutions for your business. In the “Message text” field, briefly write what you are interested in.